Exterior decoration by siding of a private house, outbuildings, verandas can truly decorate their appearance, and sometimes turn the facade into a unique design creation. The main thing in this matter is to rely on the existing knowledge, experience of professionals and listen to your inner ideas about what you want to get as a result.

Advantages and disadvantages of the material

Siding has its fans and opponents, because it is characterized by both strengths and weaknesses.

- The advantages of this material include:

- uniqueness, the ability to sheathe surfaces of any quality;

- light weight design;

- no additional strengthening of the walls and foundation is required;

- comparative low cost, availability;

- durability, long period of operation (warranty period not less than 50 years);

- simplicity and speed of installation, the ability to finish surfaces independently;

- lack of difficulty in further care, self-cleaning surface;

- no additional painting is required;

- the opportunity to give the old building an attractive look without first preparing the walls;

- protective function, resistance to rot, insects, adverse environmental factors;

- the presence of proper ventilation of the surface of the structure;

- a variety of types, shapes and colors.

- The disadvantages of the material include:

- lack of absolute impact resistance: prone to damage with strong impacts;

- during prolonged use, over time, it begins to lose color saturation.

Did you know? The fact that Canadian scientists have recently proved that the naturalness of the wood texture and its warm color can cause a feeling of comfort and warmth is in favor of ennobling the house with wood siding.

Choosing a type of siding

Modern types of siding:

- Plastic - made of acrylic and vinyl polymers, characterized by excellent performance. Resistant to rot and fire, does not crack under the influence of the sun, wind and moisture, but may not withstand power shocks.

- Metal - the most durable, but also expensive material, obtained from a sheet with a minimum thickness, which was galvanized during cold stamping. Resistant to shock, fire, but also heavier, therefore, requires much more time and power costs during installation.

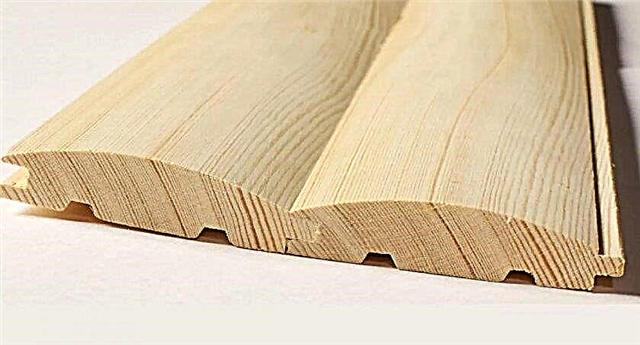

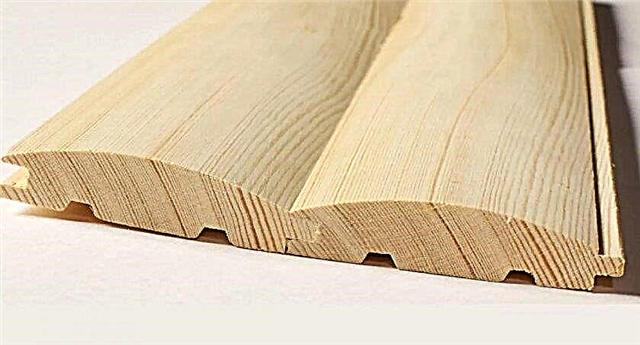

- Wood - material less commonly used for cladding buildings outside. Belongs to expensive, but not durable types of lining, requiring proper additional care. It looks beautiful, has high soundproofing characteristics, additionally retains heat. Ideally suited for the refinement of wooden buildings.

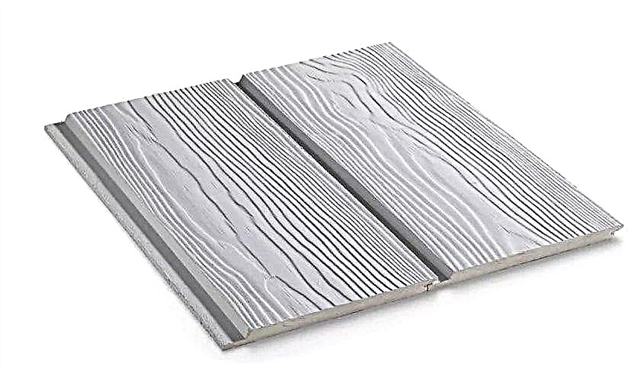

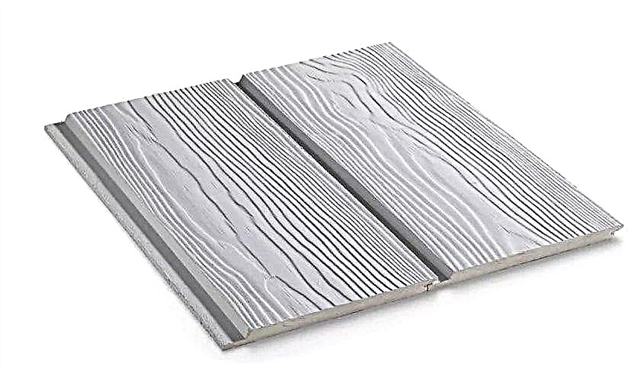

- Fiber cement - the least commonly used material. It is characterized by absolute endurance to the effects of fire, constant moisture and the appearance of mold. But it is distinguished by the weightiness and complex course of installation, carried out with an overlap using fasteners.

Pruning rules

Siding trimming is a stage that requires special care and compliance with some basic rules:

- mandatory is the presence of goggles, special equipment and knowledge of safety rules;

- when using a circular saw for trimming vinyl siding, it is necessary to install a disc with thin teeth in the opposite direction for softness and cleanliness of trimming, for working with other varieties of siding this method is not relevant;

- the panel must be cut off from the top where the mount is;

- when cutting with scissors for metal, you need to use a blade only three quarters of its length for a more accurate work;

- To correctly break off part of the panel, you must first make a furrow on it with a knife, then bend-unbend alternately until a noticeable break is observed.

Video: How to cut metal siding

Necessary materials and tools

Finishing the veranda or other house buildings with siding is necessary with a set of tools, some materials and parts.

Important! So that working with siding does not take much time and energy, do not make through cuts, because you can easily break off the panel along the recess marked by a knife.

This will require:

- saw;

- Bulgarian;

- drill;

- hammer drill;

- scissors for cutting metal (for metal siding);

- square;

- screwdriver;

- screwdriver;

- building level;

- roulette;

- hammer;

- scaffold;

- ladder;

- zinc coated screws (for mounting);

- outer corners;

- internal corners (for effective adjacency of siding in the places where the cornice joins the wall and the design of door and window openings);

- spotlights and wind boards;

- window trims;

- J-profiles (if necessary, various compounds);

- H-profiles (for joining siding strips);

- drain strips.

Siding panels are not recommended to be joined in places at different levels to avoid disturbance of an esthetic component.

Siding panels are not recommended to be joined in places at different levels to avoid disturbance of an esthetic component.

Surface preparation

First, you need to step by step prepare the surface of the structure for the installation of siding:

- To remove doors, platbands, lattice elements - everything that protrudes above the wall.

- Seal all the recesses in the walls, near the door and window openings with a solution of cement or polyurethane foam.

- To clear a surface of walls of pollution and dust particles, elements of plaster and paint.

- Clean out rotting areas and treat mold.

- Saturate all surfaces with antiseptic preparations, a deep penetration primer.

Sheathing Stages

Sheathing siding is carried out in several stages. Without any of them, the process cannot be considered completed, and the structure will not have an aesthetic appearance.

Such sequential actions include:

- crate installation;

- installation of trim strips;

- installation of siding;

- installation of spotlights.

Crate Installation

It is unacceptable to mount siding panels directly on the walls, first you need to install the crate: a galvanized profile is suitable for lining from metal, it can be used from gypsum plasterboard for plastic, dried slats with a moisture level of not more than 20%, pre-treated with antiseptic, for wooden.

First of all, using the level and the tape measure, you should mark the straight lines on the surface so that a contour forms. All sizes from the corners of the house to these lines must be measured carefully. It is necessary to find the smallest distance to the base line and set the first bar, which must be taken as the basis and landmark for the following. Fastening of the starting J-profile must be carried out under the bottom row of panels.

Its installation is carried out horizontally throughout the perimeter of the structure, but 4 cm higher than the lower edge of the siding panel. It is recommended to start installing profiles from the corner of the building with the help of self-tapping screws and U-shaped fasteners, which must be mounted with a snug fit to the wall surface. To achieve this, you can additionally use wooden blocks or pieces of foam. The distance between the profiles should be from 30 to 40 cm, in places where it is necessary, the distance can be reduced. On the walls, the fastening of the crate should be vertical, on the base - horizontally.

Did you know? Siding cladding technology appeared in America in the 19th century, when the walls of houses were decorated with polished wooden painted boards at an angle.

Installation of trims

The use of trims for siding trim helps to give the building an aesthetically finished look. External and internal corners are attached to the crate at the corners of all the openings in the walls together with the starting profile. Next, insert the siding panels. But most often, external strips are fixed after the installation of finishing panels. This option is simpler and suitable for beginners, but the choice is always the master.

The inner strips necessary to eliminate the gaps between the walls and the cornice lining are always fixed before the installation of the finishing panels. The fastening of H-strips is similar to the installation of external and internal angles and is carried out almost always before the installation of the siding itself. They are harvested in length and in the required quantity in advance, also attached to the crate. When using these profiles, the vertical docking of the panels looks aesthetically pleasing.

Vertical profiles should not be interconnected, so as not to impede natural ventilation under the siding panels and to avoid the appearance of fungus. If the location of the insulation is assumed under the lining, then this must be taken into account when installing the crate.

Vertical profiles should not be interconnected, so as not to impede natural ventilation under the siding panels and to avoid the appearance of fungus. If the location of the insulation is assumed under the lining, then this must be taken into account when installing the crate.

Siding installation

After fixing all the profiles, installation of siding panels should be carried out. The first of them must be mounted to the starting bar, until a click from below occurs. The panels are fixed on top with self-tapping screws, at a distance of 20 to 40 cm. Subsequently, the skin is installed in rows in the same way as the first row, gradually rising to the top of the wall or opening. Siding is not recommended to be pulled by force or very firmly fixed, it should be a bit loose. At the very top, the last row of panels is framed by a finishing strip.

Did you know? A completely transparent house was built in Japan by the architect Su Fujimoto, who sought to create a building capable of «combine» all the neighbors. The advantage of such a building is the abundance of light, but it is problematic to hide from prying eyes.

Installation of spotlights

Previously, the extension cornice was sheathed with all the means at hand. Modern craftsmen finish the base of the roof with ready-to-use spotlights and complete it with a wind bar. Before installing these elements, you also need to first fix the crate or guide profiles, which will become the basis for the installation of spotlights with existing holes for screws.

To improve the house, outbuildings, porch, arbors with panels from siding is beneficial both financially and aesthetically. It is not difficult to carry out all the stages of work, and the result with a competent approach will always please.