The content of the apiary is inextricably linked with the arrangement of beehives, where bees can live and make honey. There are many types of such structures, however, the use of not a single house, single-tiered or multi-tiered, but a single cassette pavilion is considered the most progressive today. This review provides a detailed description of one of the most successful designs of such a bee pavilion, which is called "Berendey."

History of the appearance of the bee pavilion

The “taming" of bees in order to use the honey they produce is rooted in antiquity. In particular, it is known for certain that such fishing was developed in Ancient Egypt, as well as in the Kingdom of Israel mentioned by the Bible, that is, it existed at least a thousand years before the birth of Christ. Initially, people used the simplest devices as houses for bees.

Did you know? The patent for the invention of the frame hive belongs to the American Lorenzo Loren Langstrot, who came up with his vertical model 37 years later than the Ukrainian beekeeper, but, unlike the latter, took care of protecting his copyright. Two more beekeepers, who created similar designs independently from each other in 1838 and 1852, were Pole Jan Dzierzon and German August von Berlepš.

So, in Asia and Africa clay nests were made for this purpose, and in bees rich in forests, even bees were arranged in makeshift hollows, which were specially hollowed out in trees, and then, along with a swarm settled in them, they were cut and transferred closer to the places where the rich pollen of plants. Only at the beginning of the 19th century, the beekeeper from the Chernihiv province Pyotr Prokopovich came up with a special beehive design involving the use of mobile frames.

Over the next century and a half, frame hives gained immense popularity and began to be used around the world in a wide variety of modifications, constantly supplemented and improved. However, with the development of technology and the need to create larger and more mobile apiaries, beekeepers gradually began to come to the conclusion that such designs have a number of significant drawbacks, resulting in massive diseases and mortality of bees.

In particular, ordinary frame hives:

- suggest a rather high crowding of the inhabitants, which is perhaps the main reason for the drop in honey productivity;

- very poorly ventilated inside;

- accumulate a large amount of moisture, which in winter leads to freezing of the structure through;

- inconvenient for garbage collection and disinfection, as a result, quickly become a place of accumulation of viruses, bacteria and fungi dangerous for bees;

- they are often attacked by rodents, especially in winter (uninvited guests, in turn, are carriers of many dangerous diseases and, in addition, making their way to heat and food, destroy the integrity of the hive);

- very bulky and poorly suited for transportation.

Important! Any bee pavilion can increase the production of honey from one family, one and a half to two times, even without the use of migrations, that is, the transportation of bees to the flowering sites of honey plants (in the latter case, honey collection sometimes increases tenfold or even more).

Thus, around the middle of the 20th century, the first cluster beehives and entire pavilions began to appear, representing multi-tiered thin-walled structures made of wax-soaked wood and intended for year-round living of an almost unlimited number of bee families.

The main advantages of cassette bee pavilions are, therefore, compactness, lightness, mobility, protection against getting wet and freezing, excellent ventilation inside, the ability to separate groups of insects from each other, which prevents the development of infections, as well as easy access to the contents of the hive (important for extraction framework, and to inspect the state of the bee colony).

The Berendey bee pavilion is a type of cassette pavilion developed in 1994 by a family of Russian beekeepers from Tver named Gracheva. As it usually happens, the idea of the original design was dictated by the need to solve a very specific problem: to minimize the time required to care for the apiary. The fact is that, having moved to a permanent place of residence in Moscow, the Grachevs tried to breed bees on their land, where they could only get out once a week.

Having heard about modern bee pavilions replacing frame hives, the head of the family approached the question with all responsibility: read special literature, talked with specialists, studied all the weaknesses of existing structures and tried to draw up drawings in such a way as to minimize all of these shortcomings. And so the design appeared, which later received the beautiful name "Berendey."

Did you know? The word "berendey" is usually associated with the name of the wise king from the famous play by A. N. Ostrovsky "The Snow Maiden", however, in reality, the Berendey are a very real nomadic people who inhabited the steppe zone of Russian principalities in the 11th – 13th centuries and mentioned in many chronicles. According to one version, it was the Berendei who became the founders of the Ukrainian Cossacks.

Advantages and disadvantages

So, “Berendey” has all the advantages that distinguish a bee pavilion from a frame hive, as well as some additional advantages.

- So, the advantages of the Grachev design should include:

- ease of manufacture;

- accurate drawings and the ability to choose the right model for specific needs;

- sustainability;

- maximum ease of maintenance, including cleaning, disinfection, feeding of bees, etc.

- mobility and lack of difficulties with transportation (suitable for nomadic beekeeping);

- creation of an optimal temperature regime without additional heating in winter (the pavilion works on the principle of a thermos, and therefore does not overheat in the summer and does not overcool in the winter);

- availability and ease of use regardless of weather conditions;

- universal purpose (can be used both as a stationary and as a mobile device, used for breeding and selection work, as a pollinating honey apiary or specializing in the production of honey, wax, royal jelly, etc.);

- ensuring higher indicators of honey production, including due to the rapid increase in the number of working individuals, as well as increasing their strength (the pavilion maintenance of bees is characterized by the absence of inferior and weak families);

- large savings in area (to accommodate an apiary, it is enough to take a very small area).

- Of the shortcomings that remain unresolved, we can only note:

- fire hazard (unfortunately, is inevitable when using natural raw materials - wood refers to materials that are highly flammable);

- lack of sufficient space during operation as an inevitable fee for increased compactness and mobility;

- lack of lighting;

- the risk of a certain confusion due to the large number of cassettes closely spaced to each other (to prevent the so-called wandering of bees, the risers always paint in different contrasting colors).

Making Pavilion "Berendey" do-it-yourself

"Berendey" in the author's version has clearly defined dimensions and technological features, so for its production you just need to follow the drawing.

It looks like this:

Depending on the volume of production, the structure can be created based on 46, 32 or 16 bee colonies (to accommodate the latter, it is enough to have a regular trailer for a passenger car, designed for 700 kg of weight, for the first two you will need a small-tonnage cargo transport).

Important! Ready-made beerepavilions of Berendey can be easily found on sale, however, making a simple, in general, construction with your own hands will save at least 40% of the money, and if you skillfully use the existing remnants of various building materials, the costs will be even less.

Typically, the structure is mounted on four racks and can move vertically from a minimum height of 40 cm to a maximum of 180 cm above the ground (it is necessary to raise the bee pavilion so high that it can be rolled up under it and then lowered directly onto the platform of the vehicle).

The design itself consists of:

- frame - plywood boards, between which there is a layer of foam;

- cassette sections (their number can vary from 1 to 4), each of which contains 8 multi-colored risers, divided, in turn, into 9 levels.

Knowing exactly the planned scale of the apiary, you can easily determine the most suitable modification of the Berendey and then get to work.

Tools and materials

To work, you need the following tools:

- pliers;

- hammer;

- plane;

- jigsaw, saw or hacksaw for working with wood;

- wood drill;

- drill or screwdriver;

- knife;

- measuring tool (tape measure, ruler);

- level;

- soft pencil or felt-tip pen.

The list of necessary materials should include:

- 20 mm thick wooden boards (you can use plywood or soft fiberboard);

- wooden beam 60 × 70 mm (can be replaced with a metal pipe);

- Styrofoam;

- hardboard;

- glassine (can be replaced with roofing material);

- mesh nylon, cardboard or metal (mesh size approximately 2.5–3 mm);

- roofing material (roofing, slate or aluminum sheet);

- organic glass (can be replaced with a dense plastic film);

- nails

- self-tapping screws;

- hooks;

- drill on wood.

Making a cassette compartment

For the manufacture of the Beerendey bee pavilion it is necessary:

- Design wireframe. From a strong wooden beam or metal pipe, cut out the supports and board them with a board so that there are no gaps between the joints. Warming and sealing of the frame is ensured by attaching to the side panels and the bottom on the inside of one layer of glassine and at least two layers of hardboard, and to the top of the frame, 10 cm away from the roof, a sheet of 3 mm thick fiberboard should be hemmed. Noise isolation of the frame is provided by covering it with polystyrene foam. The “Berendey” design assumes the presence of five doors that can be closed with hinged hooks - each door provides access to two cassettes. For door sheathing, transparent material is used (organic glass or plastic film), in which ventilation openings are preliminarily made, sheathed with a protective mesh.

- After the frame is ready, place feeders on the doors, and on the risers below put a protective net against ticks and other parasites, as well as a dust collector. The front panel of each riser should be painted with contrasting paint to prevent mixing of bees from different families.

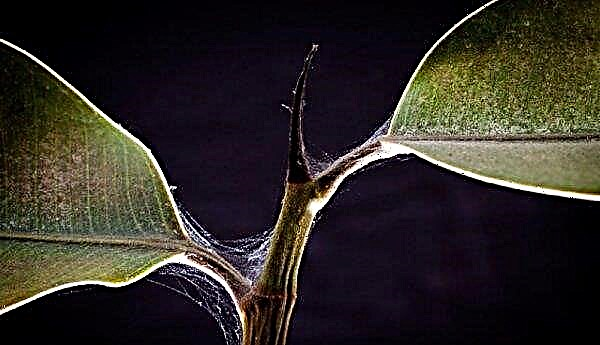

- Make cassettes in the amount of six pieces. Put together wooden boxes with such dimensions (they can vary depending on the individual project): height - 140–296 mm, length - 450–460 mm, width - 360–357 mm, the gap between the boxes is 15 mm. The tree in the manufacture of cassettes can be replaced with plywood or durable fiberboard.

- On the front wall of each box, which will be located at the lower level, place a letok - a wide hole along the entire length for the bee to enter inside. The height of the letok is 20 mm. For cassettes of the upper levels of the letok, perform in the form of round holes of the corresponding diameter. Cassettes of average levels of letters do not have.

- To ensure the mobility of the cassette and the ability to move it along the guide using nails, strengthen the support bars with dimensions of 20 × 20 mm on the side walls from the outside, and make guide grooves with dimensions of 20 × 10 mm on the inside (distance from the upper cut is 20 mm) .

- Equip each cassette with a handle, with which it can be easily inserted into the cell and then, if necessary, put it back. The cassettes are fastened with stoppers, but you can use ordinary latches for this purpose.

- Make subframeknocking a frame from the wooden beam to the size of the cassette and lining it with a prepared mesh. The device will be used to collect ticks in the treatment of bees from varroatosis.

- The construction is completed with the equipment of a mobile or folding table, on which it will be possible to conveniently place the cassettes extracted from the cells.

Did you know? The reasons for the effectiveness of fumigation of bees as a method of protecting the beekeeper from bites, became known recently. It turns out that in case of a fire threat, the bee instinctively collects as much honey as possible in the goiter so that it does not starve to flee, and it is the crowded goiter that does not allow the insect to bend so as to use its sting.

In general, experienced beekeepers assure that with the ability to work with a tree and use the tools necessary for this, as well as having a smart assistant at hand, the whole technological process from start to finish can be carried out in just two days.

Video: making a cassette compartment

Features of care for bee pavilion

Depending on whether Berendey is used as a stationary or mobile structure, care for the bee pavilion has some features, although in general the rules for handling the structure and its inhabitants are standard.

By installing a bee pavilion on your site for continuous use, you can get a reliable, strong and well-protected apiary, occupying a minimum of space and very convenient to use. For nomadic beekeeping, in addition to the pavilion itself, it is also necessary to have a vehicle of suitable capacity, but in this case the honey collection period can be extended almost all summer and, in addition, get different types of honey.

Important! The only inconvenience that distinguishes the work in the bee pavilion from the usual apiary with many separate hives is that all the actions have to be performed in very limited spaces.

The rest is standard care and consists of:

- conducting a thorough spring inspection of families in order to inspect their condition and size;

- regular sanitary treatment of cartridges, racks and all equipment used in the work;

- feeding insects as necessary and constant monitoring of food supplies;

- formation of layering (for this, brood intended for placement in the second tier is used);

- swarm control;

- timely replacement of cartridges, expansion of sockets due to new frames and compartments;

- regular pumping of honey;

- ensuring constant cleanliness inside the pavilion;

- feeding insects for the winter and warming the pavilion for the winter with protective shields.

Useful tips for beekeepers

Beekeepers who have extensive experience with pavilion keeping bees advise novice colleagues to take into account such useful recommendations:

- The modification of the pavilion must be very carefully thought out, based on real needs and the planned method of its use (stationary or mobile).

- You should always start beekeeping with a small apiary, so building your first pavilion, designed immediately for 46 families, was initially wrong.

- The insulation and sound insulation should be taken care of at the stage of manufacturing the pavilion, in which case it will not need to be equipped with heating devices, the operation of which significantly increases production costs.

- If additional illumination is planned in the pavilion, let alone heating, it is necessary to equip them with all possible precautions provided for by the fire safety rules.

- Honey collection rates are largely dependent on the bee breed, however, the most productive insects may be too aggressive for a beginner. Therefore, the choice should be taken carefully and responsibly.

- The design should be installed in such a way that human housing or a resting place is not located between the pavilion and the plantings of honey plants, that is, it is not in the way of the bees.

- Start work only in protective clothing specially designed for beekeepers.

- While in the pavilion, it is very important not to make noise, not to lose composure, and in no case be distracted. Bees are not tame pets, and they should not recognize their “master," therefore, the safety of the beekeeper is ensured only by his experience and constant monitoring of the situation.

- Untimely medical collection and non-use of free cassettes - a loss of at least half of the "crop".

- If the pavilion was not properly insulated, additional protection in winter will be ensured by the creation of a dense layer of snow between the bottom of the structure and the surface of the earth.

The Berendey bee pavilion is the embodiment of the most progressive beekeeping methods, which make it possible to simplify and modernize the work of the beekeeper. To make such a construction with your own hands is quite simple, the work does not require high-precision equipment and special skills, is not associated with the acquisition of expensive materials, but it pays off very quickly.