In order to create the perfect microclimate in the greenhouses for the plants located there, it is important not only to organize the right lighting, heating and watering. One of the main conditions for obtaining a high yield is the selection of a suitable and best covering material, which will be discussed below.

Is it necessary to cover the greenhouse with covering material?

Since gardeners begin to grow seedlings in their dachas in the early spring, when the probability of frost is very high, for their purposes they use greenhouses, which must be covered with special covering material. Why is this done?

Such a need is as follows:

- to maintain heat and a stable temperature in greenhouses;

- for growing early varieties of vegetables and herbs;

- to protect plants from ultraviolet radiation, sudden temperature changes, drafts and strong winds;

- when the greenhouse is used year round.

Types and properties of covering materials for greenhouses

In the modern world there are a large number of covering materials for greenhouses and greenhouses. They can be expensive and cheap, durable and suitable only 1 time, with good light transmission and not very easy to install and need strong frames. All these features must be considered when designing greenhouses.

Polyethylene film

- One of the first polymeric covering materials was a polyethylene film, characterized by such advantages:

- the most affordable and cheapest raw materials;

- It transmits and scatters light well;

- bends well and is exploited;

- the earth under the film does not dry for a long time, so it does not need to be watered often.

- The disadvantages are:

- quickly wears out from exposure to the sun and temperature changes;

- creates condensation from the inside;

- has a specific unpleasant odor;

- you need to gently pull on the frames so as not to tear.

Did you know? In the manufacture of plastic film and paper, the same amount of energy is used.

Reinforced plastic film

- A type of plastic film is considered reinforced, which has the following advantages:

- can last up to 5 years due to its increased strength;

- resistant to temperature extremes;

- translucent;

- convenient to use;

- environmentally friendly.

- The disadvantages are:

- unstable to mechanical damage;

- costs more than a simple film.

PVC film

- Another type of polyethylene coating is a polyvinyl chloride film and it is advantageous in that:

- has high light transmission;

- does not let in infrared rays;

- more durable and thicker than the rest of the films, can last up to 4 years;

- good air permeability;

Important! The PVC film, when disposed of, emits harmful gas, which, when ingested, can paralyze breathing.

- It has such disadvantages:

- does not withstand temperatures below -15 ° C;

- accumulates dust, as a result, the ability to reflect light is reduced.

Glass

- Very often glass is used as a covering material, which takes the second place after polycarbonate and has such positive properties:

- perfectly transmits light;

- can be used many times;

- not afraid of temperature extremes, heavy snowfalls;

- provides high thermal insulation;

- inexpensively;

- Not afraid of any chemicals.

- By cons include:

- requires a strong frame due to its heavy weight;

- may break from hail or heavy snow load;

- does not have an infrared filter;

- not suitable for growing all types of crops.

Cellular Polycarbonate

- Increasingly, gardeners began to use cellular polycarbonate for their greenhouses due to its advantages:

- very strong and durable;

- lightweight, bendable, easy to operate and mount;

- well keeps temperature in hotbeds;

- provides full lighting of plants;

- maintains strong blows and does not break;

- protects plants from harmful ultraviolet rays.

Important! When installing cellular polycarbonate in greenhouses, it must be taken into account that it is able to stretch and shorten under the influence of high and low temperatures.

- But also it has some disadvantages:

- melts from exposure to abrasive substances such as ammonia, solvent, etc .;

- it can be damaged by sharp objects.

Spanbond

This is a new kind of non-woven covering material.

- He has his positive qualities:

- protects from UV exposure;

- not influenced by mold and rot;

- ecologicaly clean;

- it passes air and moisture well;

- not afraid of significant changes in temperature, protects from winter frosts;

- relatively inexpensive;

- it can be sheathed, creating shelter of different sizes.

- Negative qualities include:

- after use, it must be disinfected to avoid infection of plants with fungal diseases.

How to choose covering material for greenhouses or greenhouses

Given the above characteristics of each type of covering materials, it can be noted that they have almost the same properties. The choice of the best should depend on its purpose.

And they are as follows:

- in order to save, the best fit is a plastic film;

- if the greenhouse is installed for a short time, you can use a plastic film, reinforced or PVC film;

- when constructing stationary greenhouses, glass or polycarbonate are ideal;

- for those who are not able to constantly care for plants in the greenhouse, spanbond will provide the best microclimate;

- it is more convenient to cover small greenhouses with a film, and large greenhouses with cellular polycarbonate and glass.

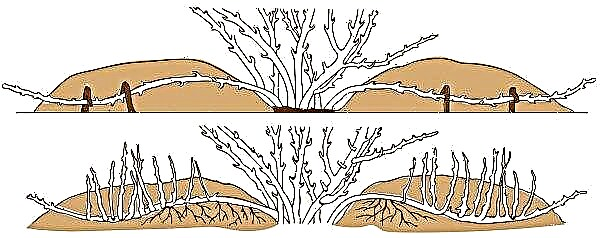

Methods of laying cover material for greenhouses

Before using the material for closing greenhouses, it is necessary to build a frame on which it will be stretched or attached. Each of these types has its own nuances:

Each of these types has its own nuances:

- when using a spunbond, a layer of this material is laid on top of the structure. In greenhouses, they are fixed with the help of the earth, in greenhouses - with sewn fabric ties;

- attaching the film, make sure that it does not tear. Therefore, it is fixed using a profile made of aluminum and PVC clips, throwing a mesh on top of the film and fixing it to the frame, tying the polyethylene with cords;

- polycarbonate is installed with thermal washers, aluminum, connecting or end profiles, a sealing tape;

- glass is fixed to the frames with glazing beads or sealant and thin screws.

Did you know? Spanbond is used not only in horticulture, but also in the automotive, furniture industry, they make overalls and hygiene products.

Where to store and how to clean the covering material

In order for the cover to last longer, it requires proper self-care and storage, which consists in the following:

- After use, the film must be washed with clean water, it can be washed with liquid soap, dried, carefully folded and hidden in a dark, dry place;

- wash the glass with soapy water, dry it, clean it with any glass cleaner, put it on storage;

- for cleaning polycarbonate, it is recommended to use a soft sponge or a cloth soaked in soapy water, without the use of detergents or cleaners, then rinse with clean water and dry;

- it is preferable to clean the spanbond from dirt by wiping it with a damp cloth without using any detergents, it can be rolled up and stored in a dry place.

With such a large amount of raw materials for sheltering greenhouses and hotbeds, it is necessary to choose the most suitable for each gardener, taking into account the positive and negative qualities of each of the above types.

With such a large amount of raw materials for sheltering greenhouses and hotbeds, it is necessary to choose the most suitable for each gardener, taking into account the positive and negative qualities of each of the above types.